What is CE Certification?

What is CE Certification and what is required to have my product be certified in the EU?

While we are a USA based testing lab, the single most common question and assistance we provide for CE Testing is “how do I CE certify my product”?

In terms of the scope of our business, we are about equally split between FCC testing and CE Testing. This is to say, that we have worked on hundreds of different types of products that required CE Certification and needed to be legally compliant in the EU.

The answer may surprise you, but CE Certification doesn’t exist (at least not in the “certification” sense that you are probably thinking from traditional a FCC Certification perspective).

The fact of the matter is that CE Certification is in fact “self-declared,” but the basis of that self declaration is based on accredited CE testing.

Confused, yet? Don’t worry we will get into what is involved in a self declaration that then requires formal lab testing.

The reality is that CE Certification is a pretty complex regulatory mechanism which is grounded in thousands of pages of legislation from the European Commission.

It’s not exactly the most approachable and off the shelf concept. At a high level the idea of a CE certification is quasi self-regulating but there are formal enforcement mechanisms that dictate you have CE test reports and accredited testing in hand.

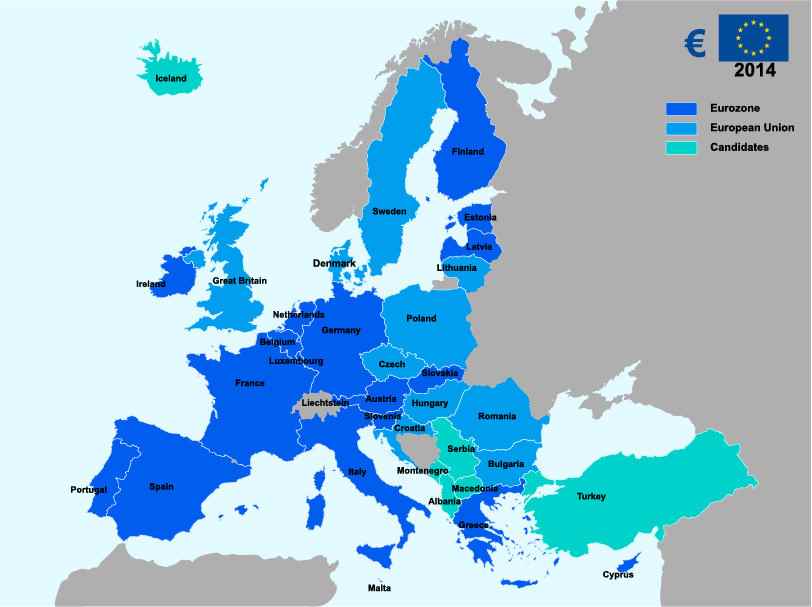

The European Union is quite unique in their decentralized regulatory approach to EMC & Safety testing for the EU.

Many of our customers coming from an FCC testing background where the test reports are formally filed with the FCC have a difficult time understanding the nuances of the CE Certification process and how the entire system is regulated and by proxy enforced.

In this post we’ll dive into a high level review of the CE certification and CE marking process, review a common CE directives (EMC Directive), determine where to look for the Essential Requirements in a Directive, learn a little about Harmonized Standards and how they are used, see where Declarations of Conformity come from, and then finally apply out CE Mark so we can finish up the CE Certification.

One note: You may hear the term CE Marking used to formally describe a CE Certification; we will discuss the CE Mark in the context of the EU CE approval process and how it is applied and used to physically label and denote the compliance of your product.

For consistency, we will group the CE Marking process under the CE Certification process but it is a very important component in the EU CE process.

So if CE Certification Doesn’t Exist, What Is The CE Mark All About?

Before we get into the technicalities (and trust us… there are mountains of edge case elements to the entire testing process), let’s review what CE Testing is all about and the scope of the system.

To understand the proper context and justifications for the CE Certification process; we first need to consider the entire European Union project and see how that compares to the FCC Certification process which came from the Radio Act of 1912.

Coming from a USA perspective, the federal government in the early 1900’s realized that radio broadcast was going to be a major service in the country and was able to form a regulator found in the Federal Communications Commissions which over the last 100 years has been working as a central authority to regulate electronic products in the United States (both wireless / RF and general EMC via FCC Part 15B.

The reason this system works for FCC Certification & testing is that the individual states of the United States have a central federal government and overlying legislation to ensure compliance.

Now imagine, you are back to early 1990s, and you are tasked with creating a regional regulatory system for wireless products and electronics for what will be binding rules and regulations across 12 diverse countries which for the last 100 years have had their own EMC, Wireless, and Safety regulations for products. This is not such an easy task. But there is where the CE Certification process originated from.

On February 7th, 1992 the Maastricht Treaty was signed between the then 12 original member states that wished to form the European Union. While CE Testing of electronics and other products, probably was not the guiding motivation for the formation of the European Union, it created a very unique problem: how do you create a system of product testing which reduces barriers to trade and minimizes the need for costly customs review and implementation.

What the European Union came up with, for CE Certification, is an entirely different approach from the FCC Certification process which is grounded in one centralized regulatory body. The EU created the idea of a voluntary marking process which would form the basis of a CE Certification. That process would be known as Ce Marking.

The motivations behind using a quasi-declaration versus having a centralized authority, we’ll leave it up the historians. Our interpretation is that it is probably grounded in the mission of the European Union which was to bring in member states into the Single Market without having one central monolithic European entity like the FCC who regulates all the product.

For purposes of usage of the CE Mark for CE Certification they are kind of one in the same, which is where we started at earlier. In truth, the CE Mark is the last step in the CE Certification.

How is CE Mark / CE Marking used for the CE Certification?

Council Directive 93/68/EEC of 22 July 1993, introduced the concept of the CE Mark and laid out the formal conformity assessment approach that is now used for CE Certification.

From the perspective of the EU, placing the CE Mark on a product demonstrates that the product has been tested and meets the EU’s requirements for health, safety, and environmental concerns. This is what the CE Testing we provide at Sunfire Testing is used for.

NOTE: We’ll cover enforcement of these testing requirements later below, but simply placing the CE Mark on your product does not make your product CE Certified. It just means you are skirting the CE rules (ie. illegal activity territory…) and this will hold no weight in the EU if you are asked for any justification as to why your product has the CE Mark in the first place.

At a high level there is a presumed order of steps that are required for a manufacturer to legally apply the CE Mark to their product and hence be CE Certified:

- 1) Identify the Directives Which Apply to Your Product

- 2) Based on the applicable Directives determine the Essential Requirements your Product Must Meet

- 3) Determine what testing must be conducted to meet the Essential Requirements

- 4) Review the Harmonized Standards of the applicable Directive

- 5) Conduct testing of your product based on Harmonized Standards

- 6) Create a Declaration of Conformity outlining the testing performed

- 7) Apply the CE Mark to your product

This seems like a mouthful of a process and really just a bunch more high level hand waving, but actually this portion of the regulatory rules are a bit more straightforward and less abstract than the self-declaration / voluntary essence of the CE Certification.

We’ll admit, the deregulated “Spirit of CE” stuff trips up almost everyone at first and they walk away thinking they just need to sticker a product. There’s a lot more to it.

We’ll review what is a CE Directive, take a look at Harmonized Standards, and piece together how these elements are coupled together and what this process really looks like from a real-world perspective of having your product CE certified and tested.

1) - What are CE Directives?

Congratulations. You’ve made it this far. This will start making some sense once you read on.

By time we have made it to CE Directives, we are finally about to step on solid land and have some actual concrete substance to step on. We are moving out off the regulatory meta-physical and getting down to actual implementation.

If you go back to our Guide to FCC Part 15 Testing, what you’ll find is that the rules parts and regulations that make up FCC Part 15 are based on the idea of intentional radiator and unintentional radiator.

An unintentional radiator is a product (like a toaster oven), which incidentally creates electromagnetic interference (EMI / EMC). An intentional radiator is a product (like a cell phone), which by purpose used radio frequencies to communicate.

If you have an intentional radiator, you then proceed to FCC Part 15C and you will then find a huge list of various rule parts which specify specific radio testing based on the operating band of your product.

CE is similar in some ways to the recognition of products along these lines on a sub-level; however, the CE system is based around the classification of your product based on the “product type” of your product as opposed to the “function” of your product.

The CE Directive is the highest level regulatory rule part that is used to determine what CE testing is required in order meet the CE Certification of your product.

Here is a list of common CE Directives (do you notice in the text that they kind of hint at what sort of products they regulate?)

Note: there are a lot more Directives that could apply to your product, we listed the ones above since these are what commonly CE test for, but the EU has extensive lists of all types of product category Directives.

So this is the first step in your CE Certification project; determine which of these Directives your product falls under.

Unlike the FCC’s approach, your product may need to meet multiple Directives which can make this process very confusing. In reality most of the product we test usually need to meet three or four different Directives depending on their exact construction and usage.

2) - What are the Essential Requirements / How to Read a CE Directive?

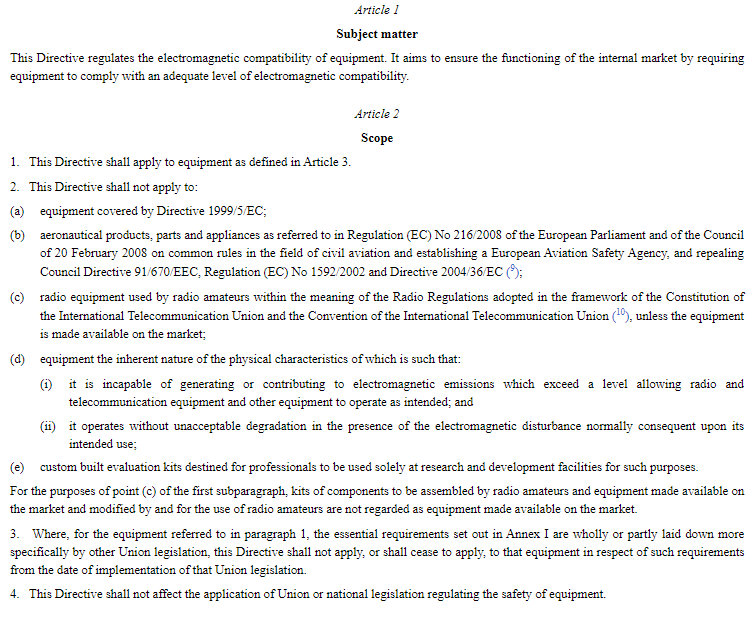

Let’s take a look at the text of the EMC – Directive 2014/30/EU and see what is involved in meeting a Directives’ Essential Requirements.

Article 1 & 2 - Subject Matter & Scope

If we go to Article/s 1 & 2, we’ll find that there’s some boilerplate subject matter & scope of the Directive definitions. This

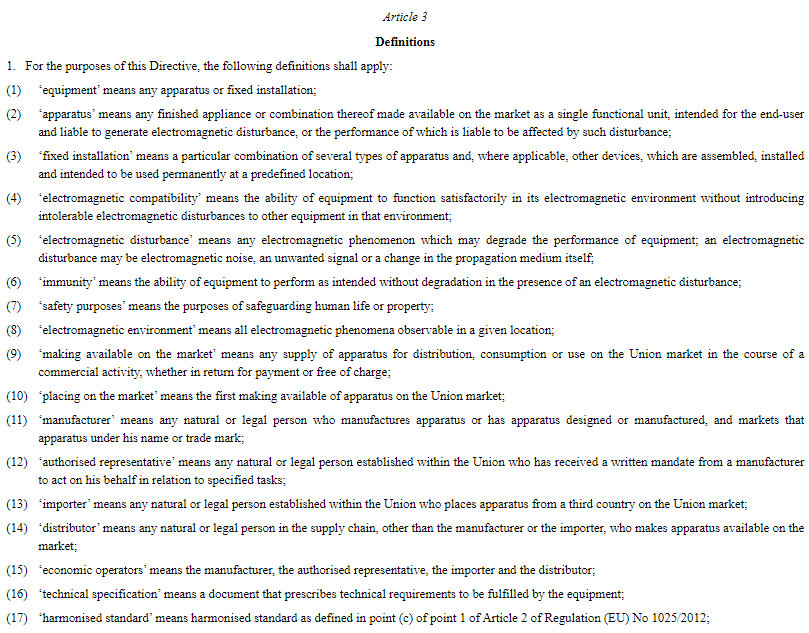

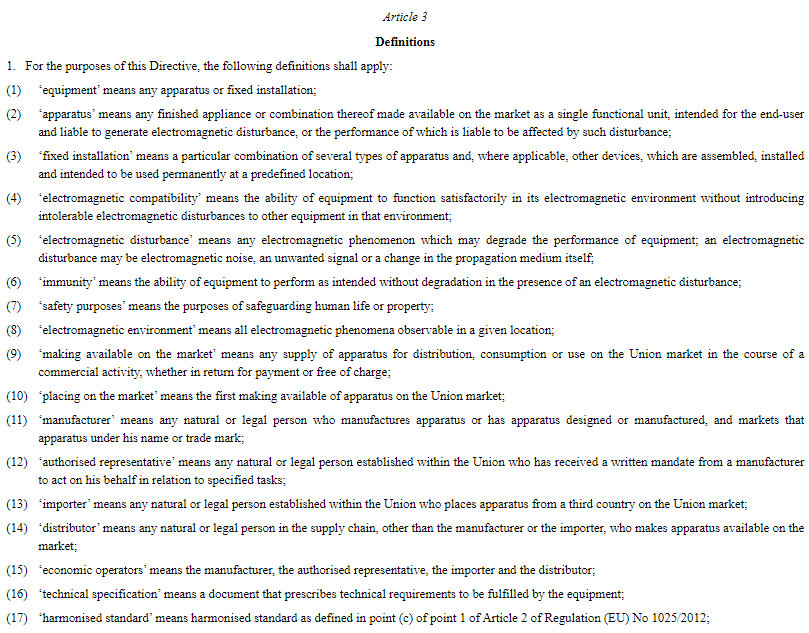

Article 3 - Definitions

Article 3, we get into a very long list of formal definitions of the major operative terms that are applied across this Directive (and you’ll find a lot of copy-over across other product CE Directives; these are all drafted by the same regulatory body and they try to be consistent).

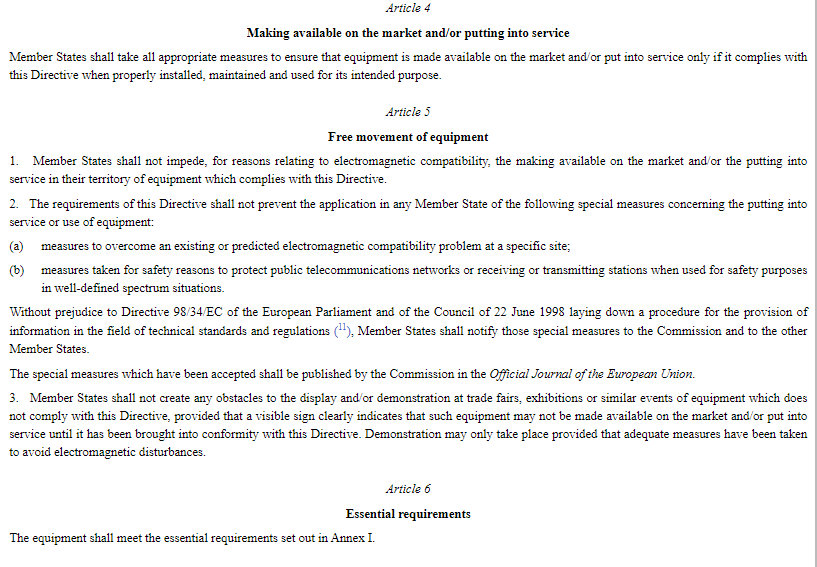

Article 4, 5, 6 - Market Availability / Movement & Essential Requirements

Articles 4 & 5 are more minor gives and kind of discuss abstract marketing & availability requirements (this is more of the One Market EU approach / justification language).

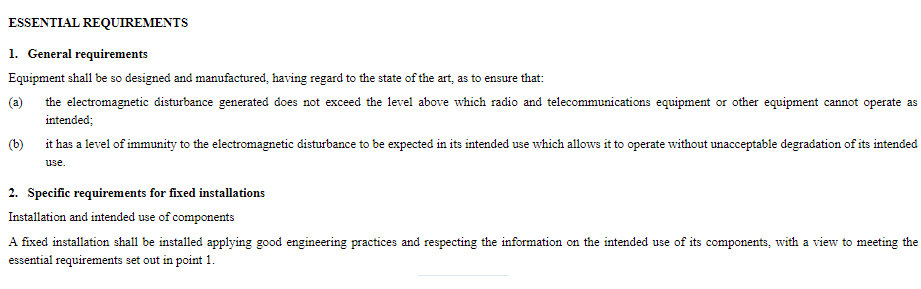

And finally, here we have it: Article 6 - Essential Requirements.

And, immediately we are asked to refer to a separate Annex I. What gives. Why must everything be so difficult with CE Certification?

In any case, we next go to Annex I and find that the Essential Requirements of a device which must be EMC tested in the EU is pretty general in fact:

In order to meet the Essential Requirements of the EMC Directive, we 1)have an obligation to ensure that no electromagnetic disturbance exceeds a level in which no other equipment can operate and 2)create equipment which has a level of immunity to electromagnetic disturbances which will allow the equipment to operate without degradation of its use.

[IMPORTANT: we skipped Chapters 2, 3, 4, 5, 6 of the EMC Directive – you’ll find that these sections spell out the requirements for your Declaration of Conformity and general rules for applying the CE Mark when you CE Certify your product; those requirements are kind of a separate article in and of themselves. We’ll loosely touch on some of these concepts]

3) - So what testing is required to meet the generalized Essential Requirements?

If we go back to the definitions list of Article 3, we’ll find a a very important defined term in the EMC Directive, look for the “harmonized standard” definition.

In typical CE fashion, we need to then go sub-reference yet another piece of EU regulation point 1 of Article 2 of Regulation (EU) No 1025/2012; we’ll leave you to do your final analysis of how the EU formalized a harmonized standard (lots of fun research there to untwist the regulatory strands); however, for purposes of CE Certification you should think of a harmonized standard as piece of require CE testing which if performed on your product grants your product the “presumption of conformity”.

Presumption of conformity is a major CE buzzword – but is a pretty easy concept. If your product is tested to the harmonized standard, by default it then meets the Essential Requirements of the Directive and so passed the requirements for CE. We are getting closer to being CE Certified.

So the next question is: what harmonized standard do I apply to my product?

4) - What harmonized standards do I need to test my product for?

The answer as to what harmonized standard applies to your product can be a little difficult to say.

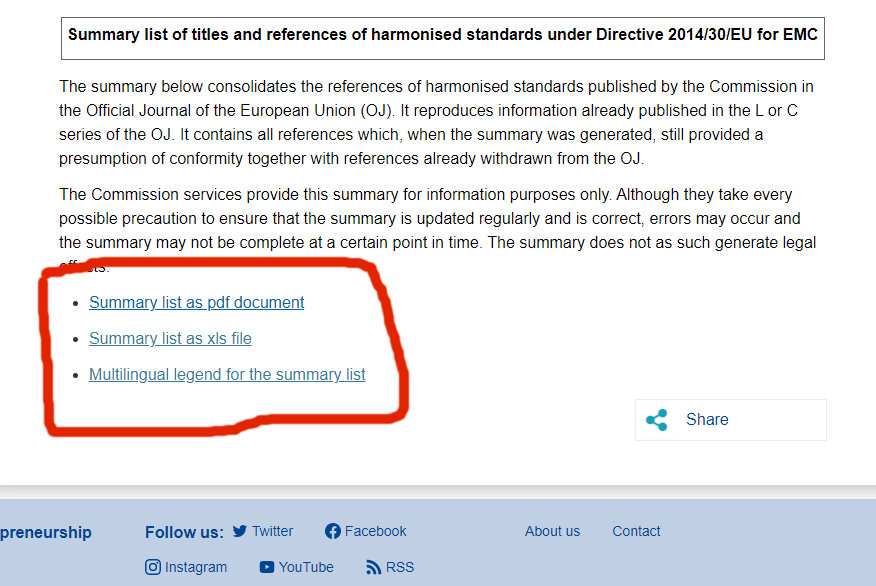

In terms of the high level guidance, most of the common CE Directives have a summary guidance list of the applicable harmonized standards.

For example if you check the EMC Directive’s main page, you’ll find a summary list of the harmonized standards:

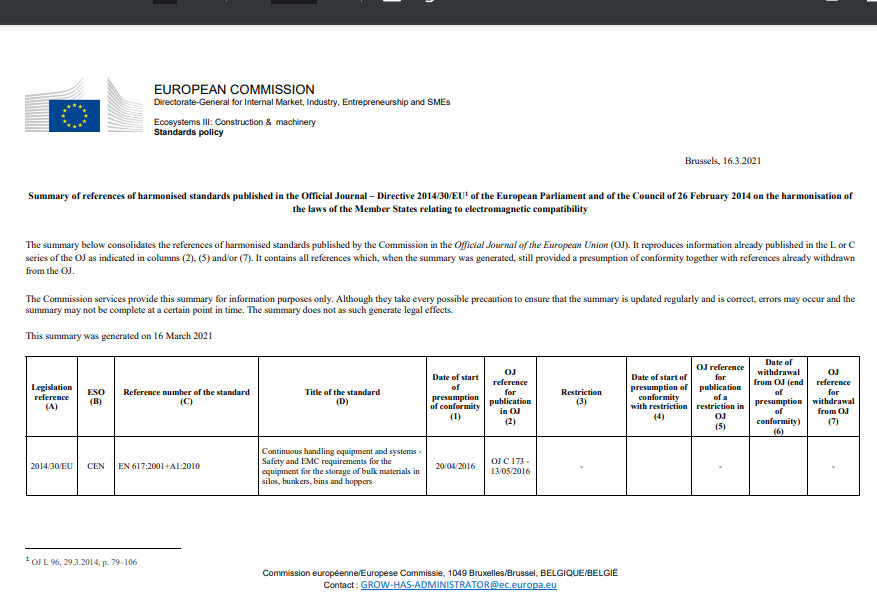

If you follow through to this list, you’ll find a formal document from the EU that specifies all of the hundreds of possible standards that your electronic product could be tested against in order to meet the Essential Requirements:

One thing to note: if you check the formal ongoing regulation of the applicable CE Directive, you’ll find that the harmonized standards in this list actually are found in long-hand regulatory language as amendments to the Directives. As of 2021, the EU has been maintaining these lists so manufactures are not required to read the long hand regulation but this is done as “courtesy” so this policy could change in the future.

5) - Conduct Testing Passed on the Harmonized Standards

So we are finally to the point where we need to contact a Contact a CE Testing Lab in order to request the identified testing for our harmonized standards.

At this point, we hope you consider us for your CE testing since it sounds like we have a little experience in this area…

What is challenging for CE testing isn’t necessarily being able to find the harmonized standards list, but in actuality there is a lot of ambiguity as to what harmonized standard your equipment needs to be tested against.

Some of the harmonized standards are very particular types of equipment; some of the harmonized standards are for very general categories. Part of being an expert in CE testing, is knowing which standards apply to which particular piece of equipment. That level of skill really only comes with testing experience.

We have received dozens of CE consultant recommendations for testing a client’s product, which are totally not-how-the-industry test things. Because our background is as electronic product designers, we have a very deep understanding of the standards at a design level as opposed to a generalist CE consultant who is checking lists and making a best guess.

As part of our quoting process for CE projects, we will ask you for the specific details we need to determine what are the applicable harmonized standards and then present in a quotation the required CE standards in order to complete your CE Certification.

Fun fact: there are a number of occasions with developing technologies where there in fact is no harmonized standard which has been developed by the EU. In this case, you need to engage outside third party certification bodies along with our CE testing in order complete the CE Certification.

At the end of our testing process, we’ll provide finished test reports which document your product’s compliance to the harmonized standards.

Once the test reports are in hand, there are two steps left: work up a Declaration of Conformity and apply the CE Mark to our product. Once those two steps are done we have completed the CE Certification.

6) - Create a Declaration of Conformity

In a future article, we’ll discuss all the inner workings of a Declaration of Conformity but let’s go back to the EMC Directive and see what it has to say as we are headed to finish line of certifying this product.

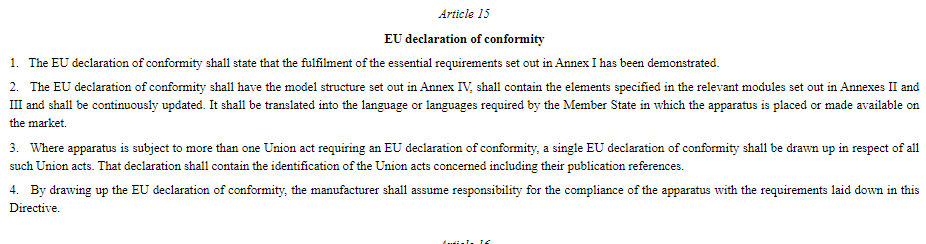

If go to Article 15, of the EMC Directive, we’ll find that the Directive specifies that we need to create a formal document, called the Declaration of Conformity (DoC).

With all of our CE testing projects, at the end of testing process, we will provide you with a filled out Declaration of Conformity which will be used to meet this requirement.

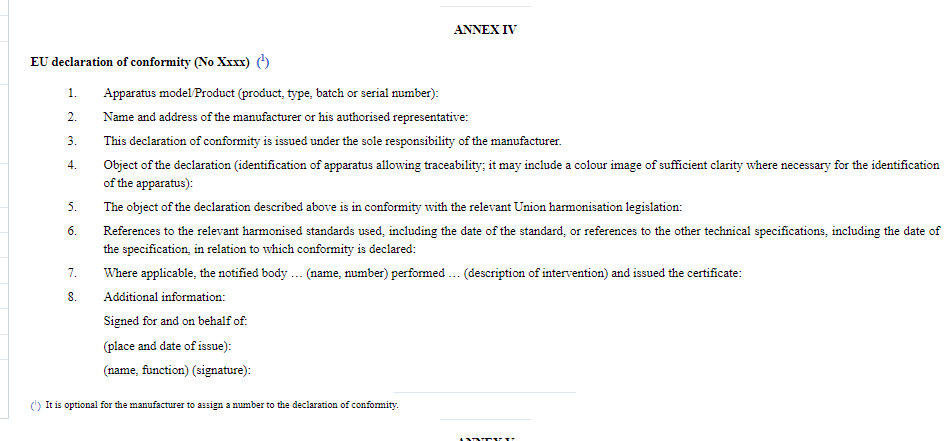

Suffice it to say, the specific Directives independently don’t really spell out in great detail what this the Declaration of Conformity requires but if check Annex IV you can get a pretty good sense of the outline of the document.

At a high level, your Declaration of Conformity must include:

- Product Model

- Name and address of manufacturer

- Statement that the declaration is the sole responsibility of the manufacturer

- A means of identification of the product

- A list of the harmonized standards and Directives the product is tested against

- Reference to any Notified Bodies used in the testing process

- Signature

As part of any project, we will provide a customized Declaration of Conformity that meets all of these requirements and is specific to your particular product so you can complete the CE Certification.

7) - Apply the CE Mark to your product

At the end of the process, you now apply the physical CE mark to your product as a sticker. That’s it!

Over all these steps, it’s been building to this one moment and the actual implementation is as simple as a sticker.

It seems almost anti-climatic.

However, the actual labeling of your product under CE is also dictated by the applicable Directives of your product. The final labeling of your product must include the CE Mark but it also usually requires other disclosures, warnings, and information which must be on the product.

In the same way, as the Declaration of Conformity, we will help prepare the labeling and ensure that your physical product meets all the documentation requirements under the applicable directives.

So if this testing is self-declared, why do I need any testing? (IE. What bad things will happen to us?)

Everyday we respond to inquiries from manufacturers who are interested in CE testing their products and once they receive the costs of the testing decide that they are going to “self test” their product.

Every once in awhile, usually about a year later, we’ll get a panicked call from one of these manufacturers who decided / read on the internet / paid for a low cost CE consultant who generated some paper documents and the call usually goes like this:

Manufacturer: “Hi… do you remember us from last year? Boy do we feel silly but, do you remember when we said that we didn’t believe you what you were saying about the EU requiring CE testing reports to support our products compliance and we decided to just put a CE label on our product because we really like that interpretation of the requirements and our CE consultant told us that would work? Well it turns out, we have a little problem now.

Can you believe it, but we now have a pallet of goods stuck in [INSERT NAME OF EU COUNTRY] and the local customs inspector is now requesting that we provide the test reports that show our product has been tested. How bad do you think this is? We told them we think everything is good with our product, but they really don’t believe us and told us that everyone says their products are good when they are caught without test reports. But REALLY our product is REALLY GOOD. We totally meet the requirements, but we just have no documentation to prove anything.”

Us: “It’s actually pretty bad. The customs inspectors will likely seize your goods and not release them back to you in any capacity unless we take quick action here. How much was this stuff worth again?

Manufacturer: “Well you know, actually the stuff is worth way way more than your testing fees, but we really didn’t think EU customs would have any issues and our CE consultant never mentioned like this. Actually he never mentioned anything about the actual business of selling anything in the EU now that I think about it. He just sent us some paperwork and told us we’d be fine.”

Us: “Well in most cases, these goods end up in a dumpster in the EU somewhere. We really were not joking about this or trying to upsell you into something you didn’t need. The actual expectation in the EU is that you have accredited test reports to hand to EU customs which are tested to the most recent harmonized standards as identified in the applicable Directives. What we can do is reach out EU customs for you and perform the testing and try to get them to release your products, but how is end customer going to feel waiting for this testing and also knowing that you tried to sell them end product which wasn’t even tested correctly in the first place”

Manufacturer: “Well, like I said, we feel really silly about this whole thing now…”

In actuality, really large companies (like Fortune 100 sized entities) with formal test laboratories and regulatory engineers might be able to pull off the CE testing required for their products to meet the CE Certification requirements; however, 99% of manufacturers rely on outside accredited testing laboratories to perform this work and provide the required testing and compliance assistance needed to ensure their products are fully CE compliant.

Unless you have a multi-million dollar regulatory budget, a full EMC test lab (which is also accredited), and are releasing dozens of products a year, there is no feasible way you will be able to self-crate the test reports you’ll need for your CE Certification.

For perspective, there is no major manufacturer of electronics in the USA that performs their own CE testing; the economics don’t make any economic sense versus using an outside party who specializes in CE testing and certification. The trend in the last twenty years has been to completely outsource CE testing to 3rd parties – most large companies have been closing their internal labs for decades now.

If take one thing away from this article, just realize that in order to sell into the EU you do require formal testing and your product documentation and labeling requires much more than just a CE sticker on the outside of your product.

How Can Sunfire Testing Assist in the CE Certification Process?

We realize the last section is a little silly, but this is a weekly call we receive! Getting CE Certification right is nowhere near as straightforward or as easy some may have you believe.

- As product designers and as a test lab, we have worked on hundreds of CE products and are incredibly familiar with the documentation requirements and the supporting CE testing that goes into your product.

- As part of any of our projects, our fees include not only the physical EMC & Safety testing of your product but include all manual language, declarations, and labeling in order to fully apply the CE Mark and be fully CE Certified.

If you are considering a CE Certification, contact us today for a free quote and analysis of what CE testing is required for your product.

One of our sales staff will be able to quickly identify the required testing and provide a comprehensive quote of what will be required in order to complete your CE Certification.

We make compliance testing easy.

Submit your project details today for a no-cost quote

Request Quote